They are a young industrial company from the West of Switzerland and focus on developing new robotic systems. Isochronic is one of Change2Twin’s beneficiaries who ventured into creating a digital twin. Read their beneficiary story.

Who is Isochronic?

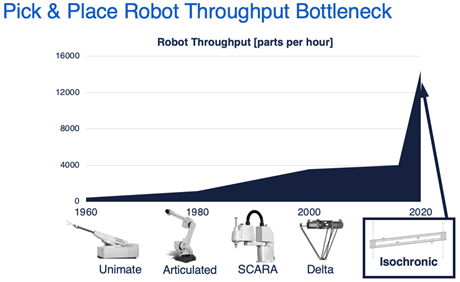

Isochronic is developing new paradigm-shifting industrial robotic systems for pick & place applications, which enable simultaneous parts transports for the first time. The young industrial company develops new robotic systems incorporating their proprietary robotics control software and advanced pick & place algorithms. Isochronic was founded in 2020 and is based in Denges (VD), in close proximity to EPFL University and has rapidly grown to a team of 13 collaborators to date.

What is the purpose of the digital twin that you have created and are now testing?

The aim of this digital twin project is to accelerate the sales cycle by allowing a fast digital configuration of every new robot system setup, demonstrating customers a working 3D digital version of their configured robotic system which can demonstrate the manipulation of their own parts. Moreover, the digital twin allows us to maximize the throughput of parts which can be sorted by Isochronic’s robotic system thanks to optimized sorting algorithms and associated robot motion control strategies.

Has the digital twin fulfilled your expectations?

While the project is currently still ongoing, first results are highly promising and we expect that our expectations will even be surpassed by the project results.

What are your plans for the near future with the digital twin?

Once the project is completed, we plan to further develop the digital twin to facilitate its ease-of-use and link it even more closely to our technology stack.

Dr. Melvin Haas

Isochronic AG, Switzerland

“The Change2Twin project helped our young industrial company develop an initial digital twin implementation and first results look very promising. We are convinced that many robotics companies can benefit from the support of this program and highly recommend it.”

Thank you very much for being part of our programme and good luck with your digital twin!