Digital Twins can be applied to almost everything. The plastic and glass bottles are not exempt to the power of this technology and the effects are amazing. Did you know that glass bottles are amongst the most environmentally impactful? Well, Digital Twin can for sure be an excellent choice to overcome this challenge.

Summer is here, or at least in some parts of Europe! The major issue you will face is not what you think about. Of course, in some places, you can experiment with the feeling of walking through an oven with hot air propelled into your face, which I have to say is quite annoying. Sand everywhere, sweat drops from your neck to the end of your back, 3 am mosquitos’ party. The list can be long, but don’t we wait for that all year? What can be worse? Imagine you are passing over those irritating details since you are on holiday in a splendid place.

Why is the cap attached to my plastic bottle?

You are about to enjoy a fresh soda, and the idea of the taste and freshness are already making your day. You take good care of opening it slowly because it is fizzy. You do not know yet, but the worst is about to come. You first try to detach the cap as usual and like an average person, but then with much more strength, as if suddenly Hulk’s blood was running into your vein, of course without succeeding with the task. While trying to appreciate the moment anyway, the bottle cap stuck to your sweaty face, but the nightmare is not over. Trying to close the bottle makes you think you never know how to do so. Now you start remembering.

For sure, you are not the only one to feel disturbed by that, complains are all over social media. Nevertheless, the 3 July 2024 is a day to mark in the agenda as it is now mandatory or all EU states to have phased out loose caps for plastic drinks bottles up to three litres. It’s part of an EU directive announced in 2018 that aims to reduce single-use plastic waste. No summer funny prank here just a necessary need to deal with plastic waste as part of the European Green Deal. The attached cap makes it easier to gather plastic waste and recycle it. Here again, digital twin technologies can be a very powerful tool creating a circular economy for plastic. Optimization, resources saving, traceability, the tool is offering a range of improvement for manufacturing companies working in the plastic sector, contributing the plastic sector to align with the European Commission Plastic Strategy.

How Digital twin can tackle the recycling glass bottle challenge?

Experts from the University of Southampton revealed in a 2020 study that, surprisingly, glass and recycled glass bottles have a more significant environmental impact than all other types of containers. However, the researchers found that every type of container carries environmental consequences from their global warming potential to their contribution to fossil fuel depletion.

Meet Remoin Montajes! Based in the picturesque region of Asturias, Spain Remoin Montajes S.L. is a small but innovative manufacturing company that specializes in designing and constructing machinery, particularly for the food and beverage sector. Their primary clients are local cider producers who uphold the rich tradition of cider-making in Asturias. These producers have recently achieved the IFS Food standard, a rigorous certification that requires meticulous inspection of bottles.

Cider in Asturias is crafted using artisanal methods involving reusing bottles by thoroughly washing them. However, many small cider producers lack the resources for advanced automatic washing machines equipped with laser detection systems, often relying instead on human eye control, which can lead to errors and contamination.

This reliance presents a significant challenge: how can these artisan cider makers comply with the stringent IFS Food standards while reusing bottles and ensuring they are impeccably clean? This is where Remoin Montajes steps in with an ingenious solution thanks to its participation in the Change2Twin open call.

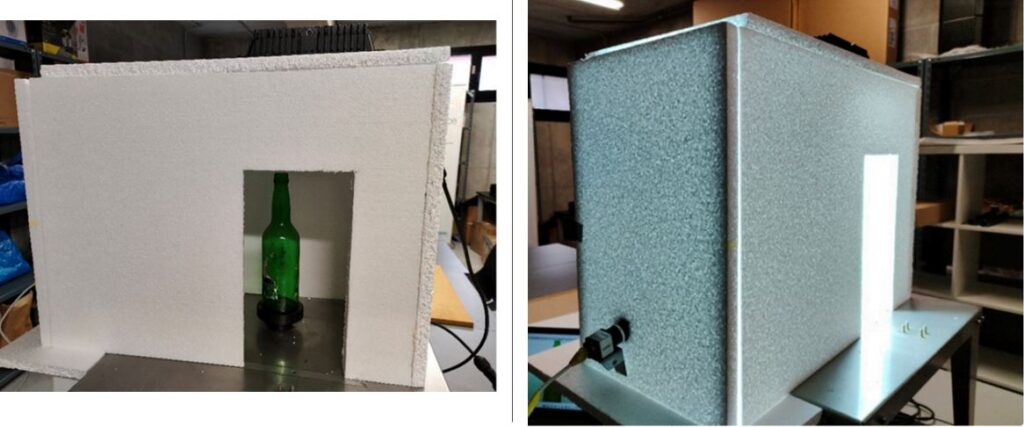

The purpose of their digital twin project is to develop a machine that automates the quality control of a cider bottle production line. The aim is to create a system capable of guaranteeing the rigorous cleaning and disinfection conditions necessary for working with recycled bottles. By implementing a sophisticated dirt detection system based on artificial vision, Remoin Montajes can achieve superior results, eliminating human error and enhancing the production process.

The project’s ambition extends further: to design and implement a comprehensive system that includes a 3D simulation, advanced dirt detection software, and real-time control and visualization software for monitoring results and alarms. Thanks to the implementation of cutting-edge artificial vision techniques, the goal of developing an effective dirt detection system was realized, marking a significant advancement in quality control for the cider industry.

Digital twin technologies are covering a wide range of needs in the manufacturing sector and European financed projects such as Remoin Montajes are the perfect results for European SMEs to engage in digital transformation in a quick and economical way.

Marjorie Grassler